Aerospace Industry

Industry Specific Production Knowledge

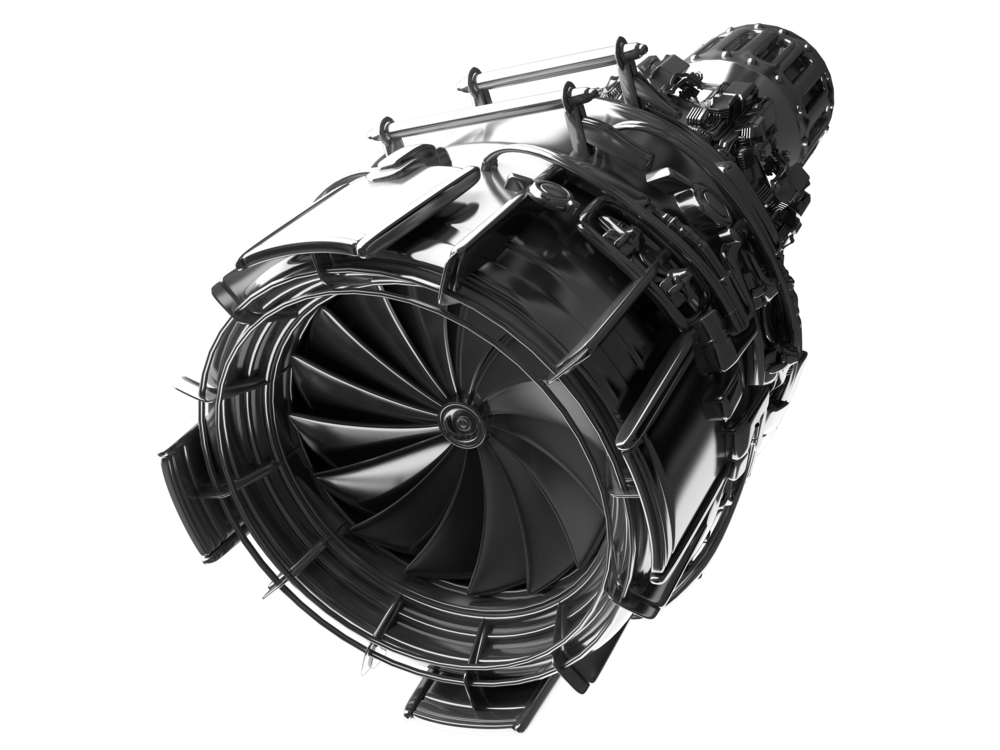

Large scale 3D printing is revolutionizing the aerospace industry. The ability to print large, complex parts on demand has drastically reduced lead times and costs associated with traditional manufacturing methods. In addition, 3D printing allows for greater design flexibility and the ability to create unique geometries that were previously impossible. This technology is being used to produce everything from aircraft interiors and engine components to rocket nozzles and satellite antennas. As the technology continues to improve and become more widespread, it has the potential to greatly reduce the environmental impact of the aerospace industry by reducing material waste and energy consumption.

One of the key benefits of large scale 3D printing in the aerospace industry is the ability to produce lightweight parts without sacrificing strength or durability. This is particularly important in aerospace, where weight is a critical factor in aircraft performance and fuel efficiency. With 3D printing, it is possible to create complex lattice structures that reduce weight while maintaining strength. This allows aircraft to fly farther and more efficiently, ultimately reducing fuel consumption and emissions. As the aerospace industry continues to explore the possibilities of large scale 3D printing, it is likely that we will see even more innovative solutions that push the boundaries of what is possible in aircraft design and manufacturing.

Informational Videos

A comprehensive collection of informative and engaging videos that showcase the latest trends, techniques, and applications of large-scale 3D printing in various industries.